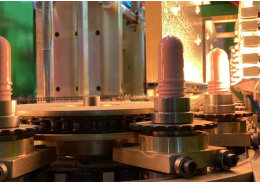

MOULD, the mother of the plastic industry, is a necessary specialized tool for shaping plastics from raw materials to products. The quality of molds and the rationality of their structure directly determine the quality and performance of plastic products, as well as product prices and delivery times. The most basic manufacturing process of plastic products: plastic raw materials - mold forming - obtaining semi-finished products - surface decoration - inspection completion, mold is the most important part of the process.

1. Mold classification: The material used for molds varies depending on the product material. In industrial production, common types of molds include: casting molds and forging molds in the metal industry; Plastic molds and inorganic non-metallic molds in the non-metallic industry. In the plastic industry, the most common type is plastic molds, which are divided into injection molding molds, blow molding molds, and extrusion molding molds. For example, plastic lids are manufactured by injection molds; PET bottles are completed by blow molding molds.

English

English