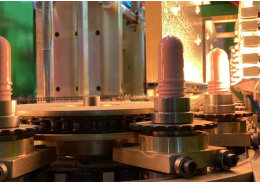

1. Polyethylene, PE is a type of polyethylene plastic that is widely used as a thermoplastic resin. It is usually divided into HDPE (high-density polyethylene), MDPE (medium density polyethylene), and LDPE (low-density polyethylene). It is widely used in the manufacturing of packaging containers for food, cosmetics, pharmaceuticals, and industrial products. It is commonly used in the manufacturing of cosmetic hoses, blow bottles, plastic films, lids, stoppers, and other products. PE products are easy to recycle and reuse (as PCR materials), and PE is an environmentally friendly material. It has low density, good toughness, is non-toxic and odorless, good chemical properties, and good color dispersion performance; But it is prone to aging, deformation, large molecular spacing, and difficult to electroplate.

2. Polypropylene, PP is a type of propylene polymer that is widely used as a thermoplastic resin in the manufacturing of packaging containers for food, cosmetics, pharmaceuticals, and industrial products. The surface decoration process selection of PP products is very diverse. PP products are usually produced by injection molding, as well as blow molding and foam molding. PP products are easy to recycle and reuse (as PCR materials), and PP is an environmentally friendly material.

3. Polyethylene terephthalate, PET is a high-performance thermoplastic crystalline resin. PET is widely used in the manufacturing of packaging containers for food, cosmetics, pharmaceuticals, and industrial products, from carpets on the ground, clothes worn on the body, to beverage bottles and cosmetics. It has low density, good toughness, water resistance, oxidation resistance, chemical resistance, non-toxic and odorless, stable product size, high purity, and good transparency, making it an ideal material for personal care and cleaning product containers. It can manufacture various containers, accessories, and films using injection molding and blow molding methods; Its surface can be almost any existing decorative process, and it is easy to recycle and reuse (made into PCR material). PET is an environmentally friendly and very important material.

1. Polyethylene, PE is a type of polyethylene plastic that is widely used as a thermoplastic resin. It is usually divided into HDPE (high-density polyethylene), MDPE (medium density polyethylene), and LDPE (low-density polyethylene). It is widely used in the manufacturing of packaging containers for food, cosmetics, pharmaceuticals, and industrial products. It is commonly used in the manufacturing of cosmetic hoses, blow bottles, plastic films, lids, stoppers, and other products. PE products are easy to recycle and reuse (as PCR materials), and PE is an environmentally friendly material. It has low density, good toughness, is non-toxic and odorless, good chemical properties, and good color dispersion performance; But it is prone to aging, deformation, large molecular spacing, and difficult to electroplate.

2. Polypropylene, PP is a type of propylene polymer that is widely used as a thermoplastic resin in the manufacturing of packaging containers for food, cosmetics, pharmaceuticals, and industrial products. The surface decoration process selection of PP products is very diverse. PP products are usually produced by injection molding, as well as blow molding and foam molding. PP products are easy to recycle and reuse (as PCR materials), and PP is an environmentally friendly material.

3. Polyethylene terephthalate, PET is a high-performance thermoplastic crystalline resin. PET is widely used in the manufacturing of packaging containers for food, cosmetics, pharmaceuticals, and industrial products, from carpets on the ground, clothes worn on the body, to beverage bottles and cosmetics. It has low density, good toughness, water resistance, oxidation resistance, chemical resistance, non-toxic and odorless, stable product size, high purity, and good transparency, making it an ideal material for personal care and cleaning product containers. It can manufacture various containers, accessories, and films using injection molding and blow molding methods; Its surface can be almost any existing decorative process, and it is easy to recycle and reuse (made into PCR material). PET is an environmentally friendly and very important material.

English

English