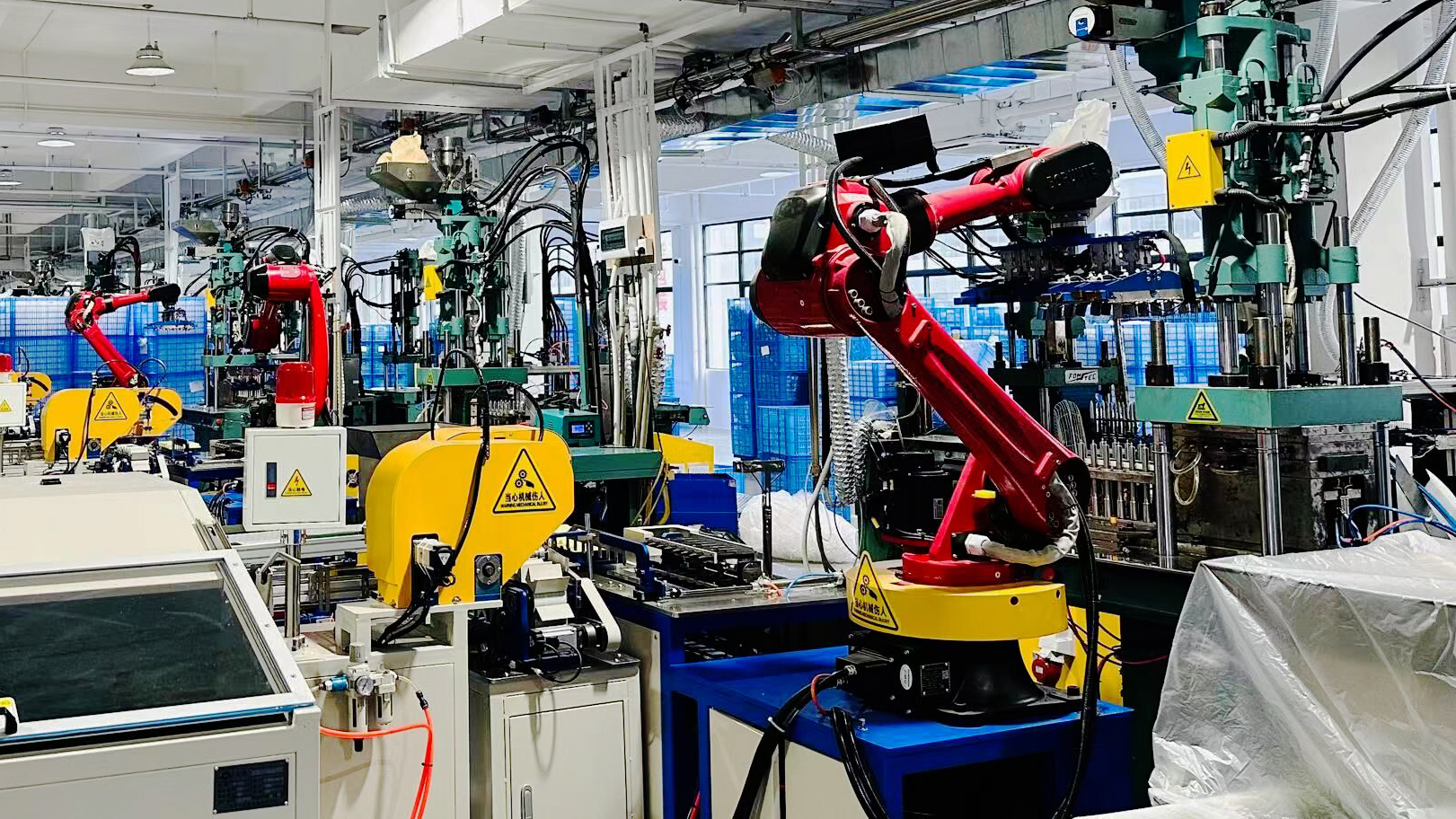

Production

Process

video

01. Tube Making

First step is Extrude 2 layers, 5 layers plastic hollow tube by mixing LDPE plastic raw material, EVOH and Adhesive .

02. Surface Decoration

Cutted tube surface will be applied to glossy, matte, pearlized oil finish

HEYPACK©

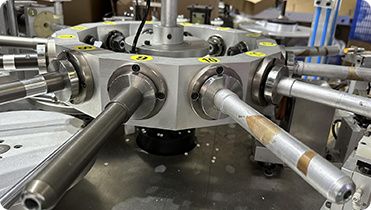

03. Injection Shoulder

Different Tube Head Apllicator will be injected in to empty tube for matching different closures

04. Tube Sealing

Tube end sealing can be done before delivery if your filling from opening , curved or straight line available

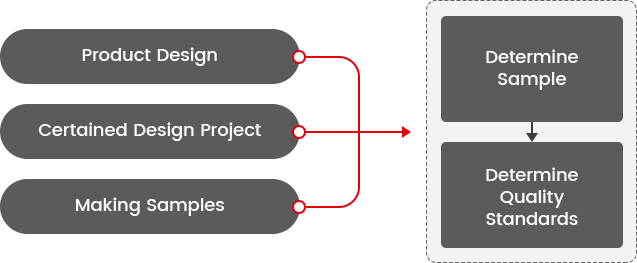

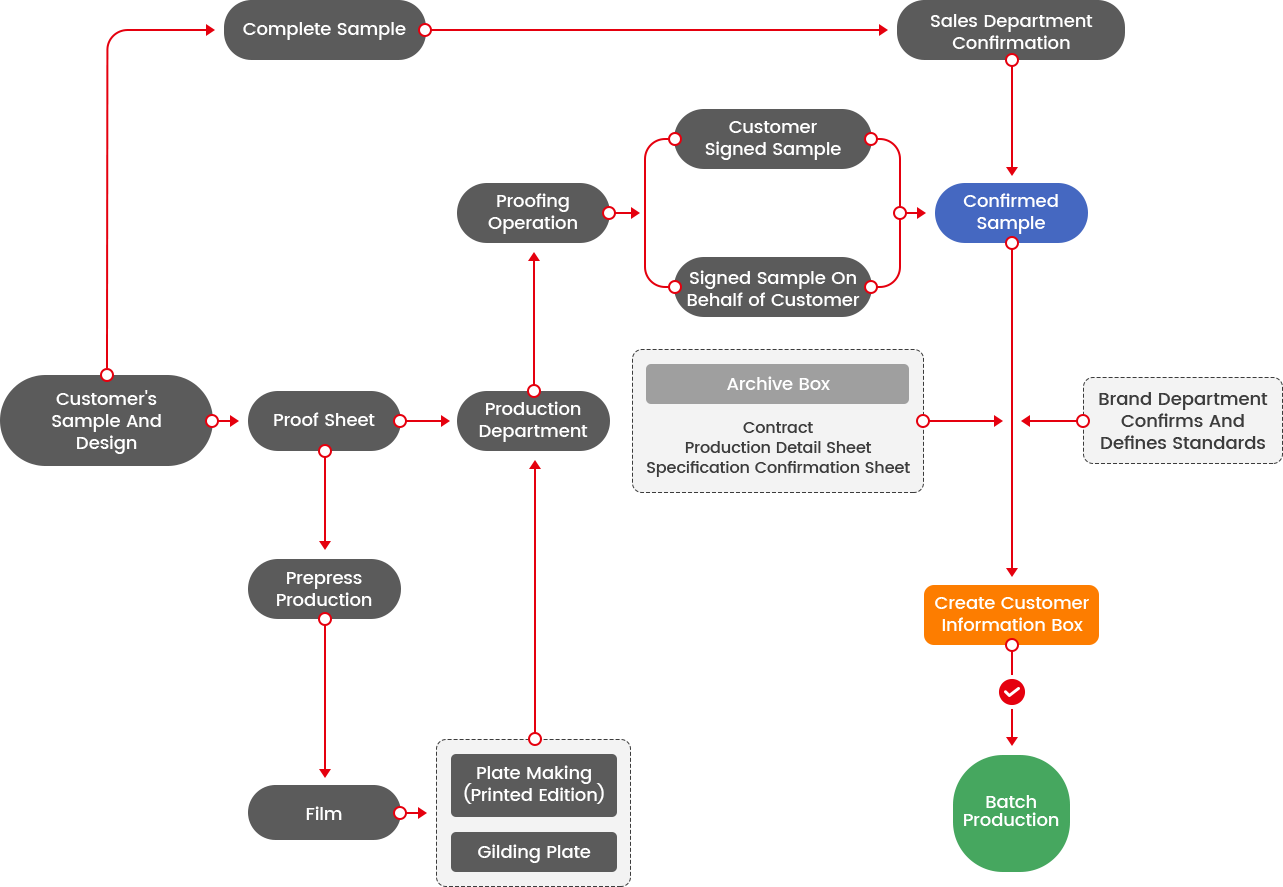

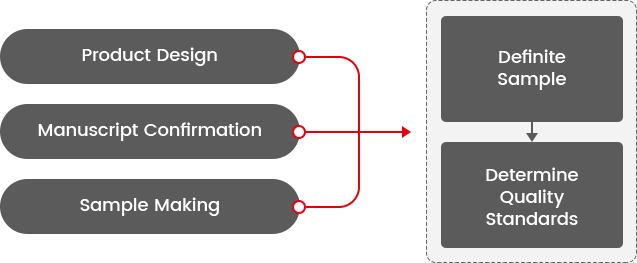

PRE-PRODUCTION

PRE-PRODUCTION

Process

& Lore

video

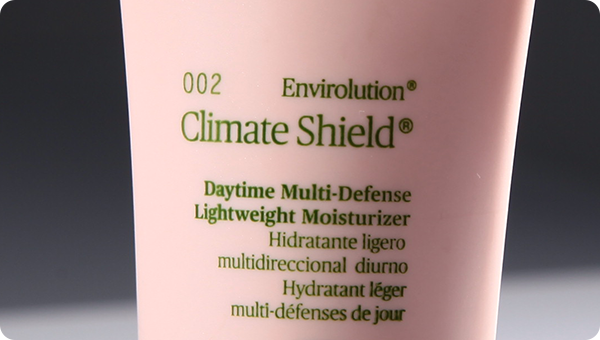

01. Silk Screen Printing

the printing plate will be wiped by UV printing ink, and then the printing plate transfer the ink on tube body , then move to UV light dryer to solidify the UV ink.

02. Hot Stamping

Silver, gold, Rose or any color transfers the foil by a stamping plate for attactive logo

HEYPACK©

03. Lock Caps / Stick Aluminum Film

Cap be assmbled first if filling from tube end, Aluminum foil stick on opening to avoid leaking

04. Labeling

Stick white, transparent and metallic label for printing design

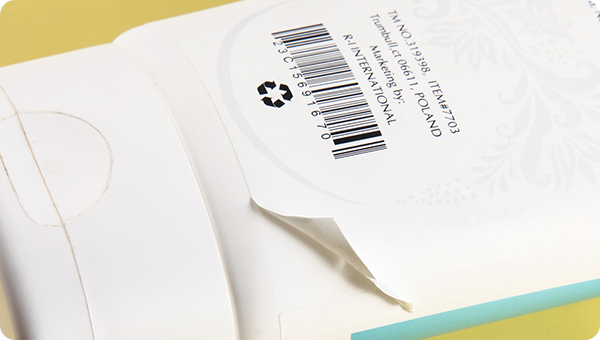

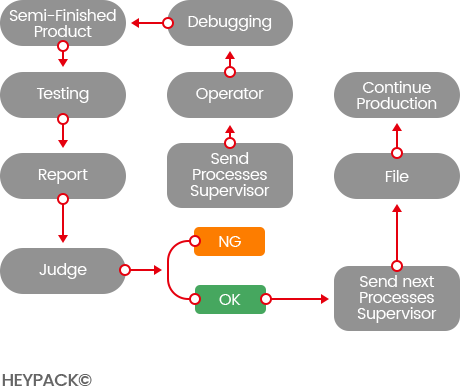

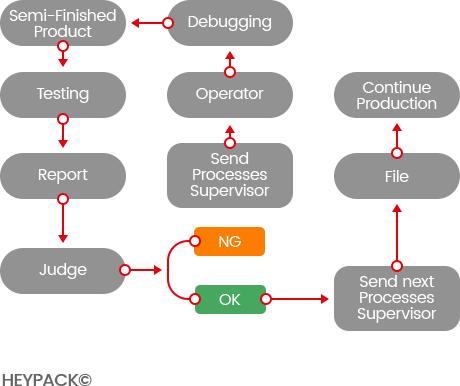

Printing Test

Use Adheisve Sticker printing to test painting coming off or not

Vacuum Test

Airless machine space for filling liquid leaking test

IPQ

Final quality inspect by worker for cosmetic tube apperance, specification and funcational. 100% quality check available

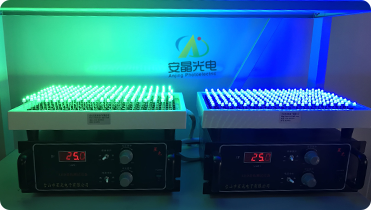

Light Aging Test

Ultraviolet light test tube be broken in 48 hours for use under sunlight situation

Test &

Certificate

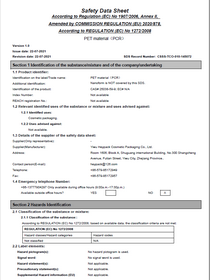

PCR

ROSH

Reach

MSDS

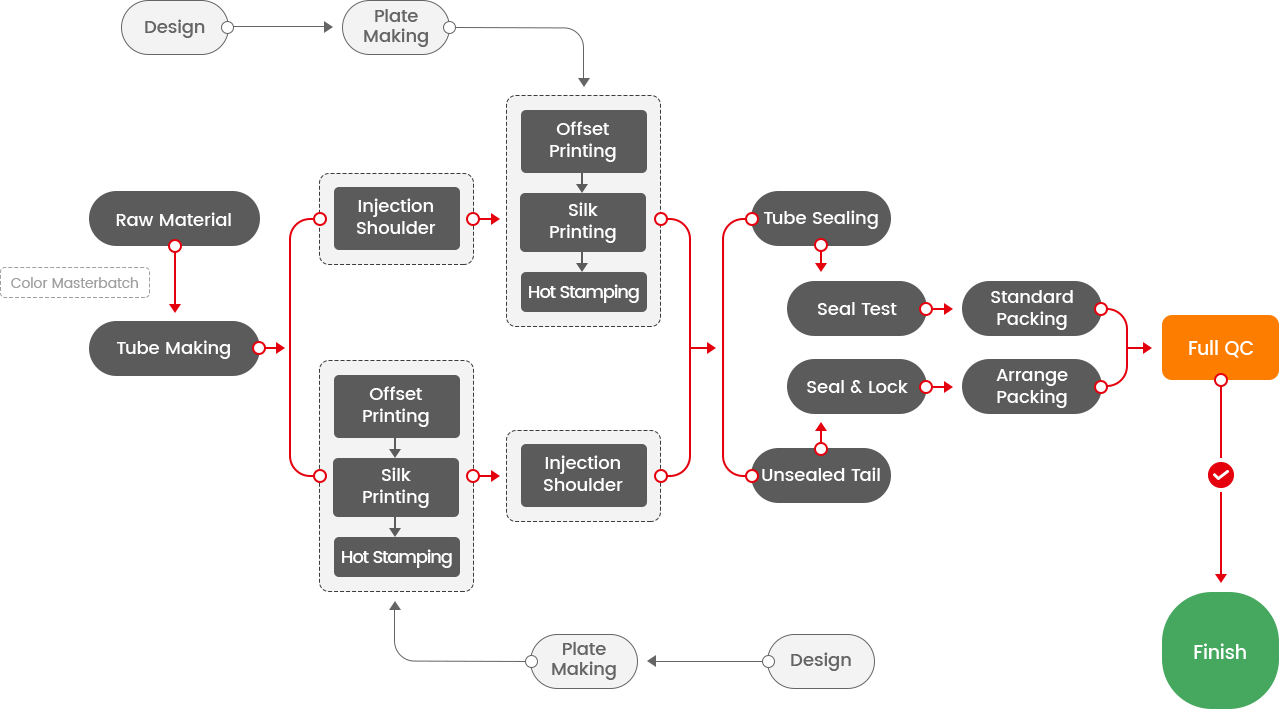

IN-PRODUCTION

Productio

Process

video

01. Tube Making

Laminated tube made by Aluminium plastic sheet with large quantity output . Silver or white aluminum sheet available

02. Offset Printing

1-8 colors offset printing ,inked image is transferred to plate and then to the tube surface, then ink exposed to UV light for solidify

HEYPACK©

03. Injection Shoulder

Different Tube Head Apllicator will be injected in to empty tube for matching different closures

04. Tube Sealing

Tube end sealing can be done before delivery if your filling from opening , curved or straight line available

PRE-PRODUCTION

PRE-PRODUCTION

Process

& Lore

video

HEYPACK©

01. Screen Printing

the printing plate will be wiped by UV printing ink, and then the printing plate transfer the ink on tube body , then move to UV light dryer to solidify the UV ink.

02. Gilding

Silver, gold, Rose or any color transfers the foil by a stamping plate for attactive logo

Printing Test

Use Adheisve Sticker printing to test painting coming off or not

Vacuum Test

Airless machine space for filling liquid leaking test

IPQ

Final quality inspect by worker for cosmetic tube apperance, specification and funcational. 100% quality check available

Light Aging Test

Ultraviolet light test tube be broken in 48 hours for use under sunlight situation

Test &

Certificate

PCR

ROSH

Reach

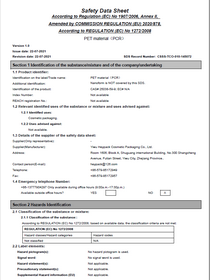

MSDS

English

English