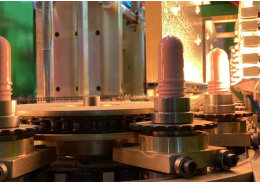

Screen printing belongs to the direct printing method and is the main printing method in orifice plate printing. Its principle is to use a reciprocating scraper to print ink directly onto the surface of the product through the micropores on the screen plate. The main materials for screen printing include ink and screen printing. It is very important to choose different inks based on the different surface materials and printing requirements of the product; Screen printing is usually made of polymer resin material. To achieve exquisite printing effects, a high-precision screen printing is a necessary condition.

Process flow: pattern or text - sun drying film - making screen version installed on hot stamping machine - processing production ink transferred to the surface of the product, and cured after heating or UV lighting. The screen version is a consumable material that needs to be replaced after a certain period of production.

Process features: The pattern or text completed by silk screen printing has a prominent three-dimensional effect. This process can be applied to almost any surface of plastic, metal, paper, ceramics, glass, bamboo and wood materials. With the advancement of screen printing technology and equipment, it has evolved from monochrome to printing six colors simultaneously, and even multiple colors can be stacked together to achieve more complex, three-dimensional, and unique pattern effects. Silk screen printing technology is suitable for printing on various curved surfaces of products.

English

English