Production

Process

video

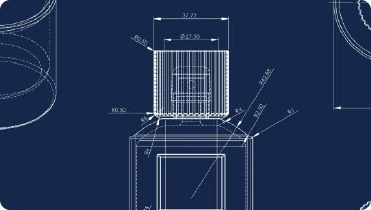

01. Design Drawings

Engineer make container's structure and specification drawing according customer sketch to assure exactly size and apperance.

02. 3D Printing

3D digital printing build container shape 1:1 to present before molding

03. Mould Making

CNC, Spark and lathe processing workshop make 2-16 cavitys blowing bottle mold with stainless steel

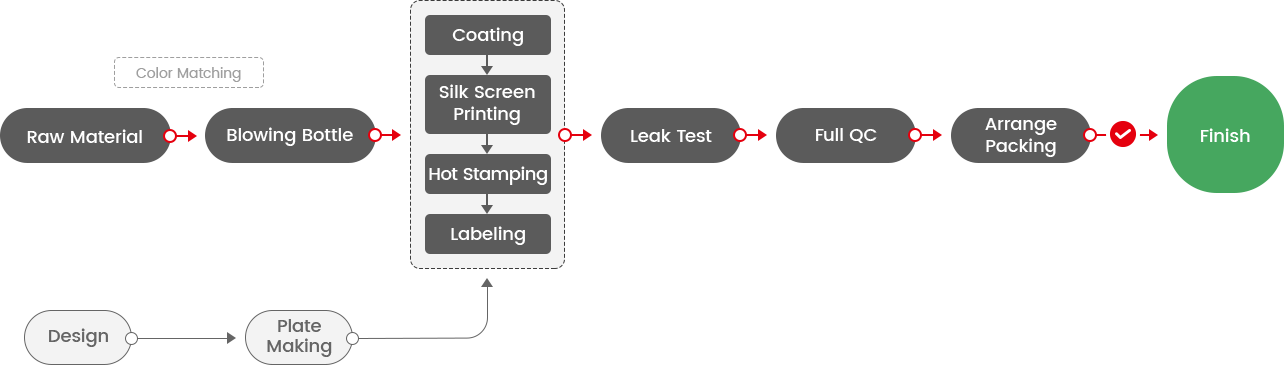

04. Blowing Bottle

Colored PET preform + mold to blowing out customized empty bottle

05. Surface Decoration

Engraving logo, Matte Frosting, Pearlizing, electroplating applied on bottle surface

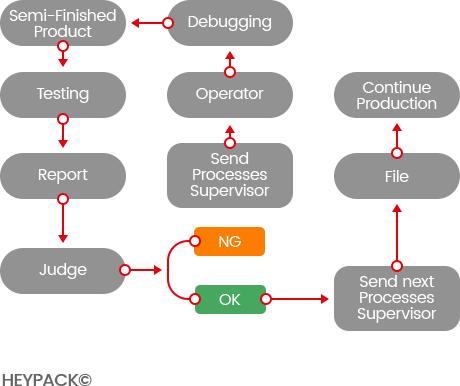

06. Quality Control

Quality inspect mainly bottle deformatin, Burr edge, printing positioning and fallling, bottle thickness, size etc.

HEYPACK©

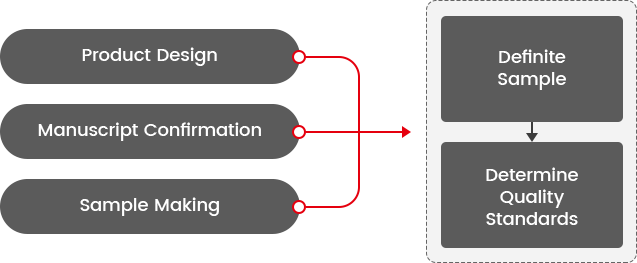

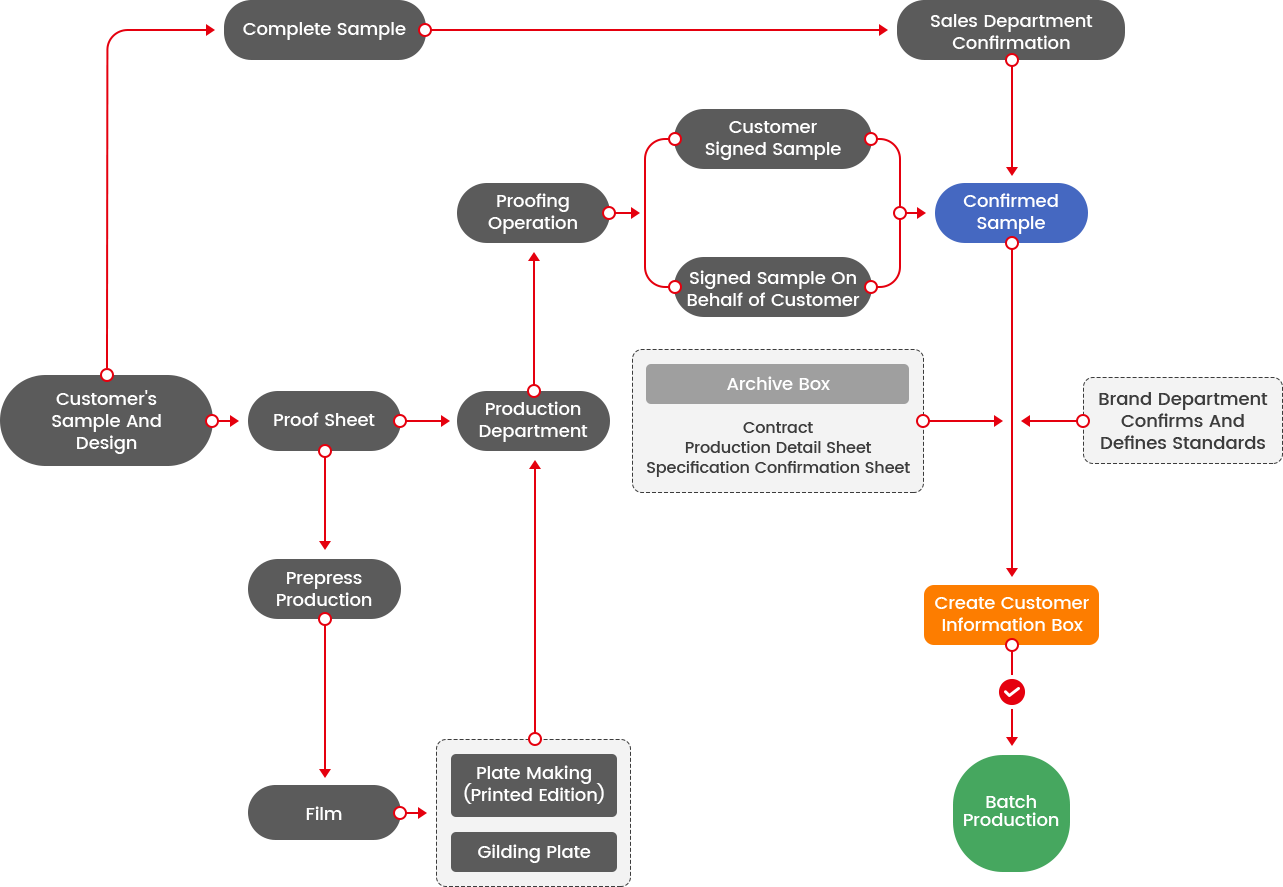

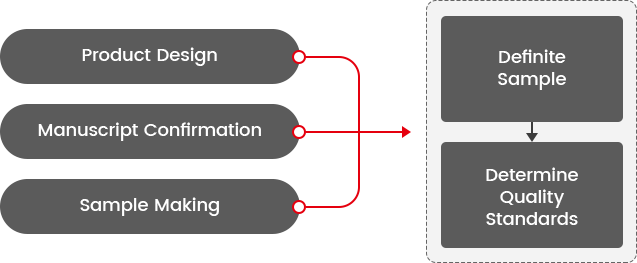

PRE-PRODUCTION

IN PRODUCTION

Process

& Lore

video

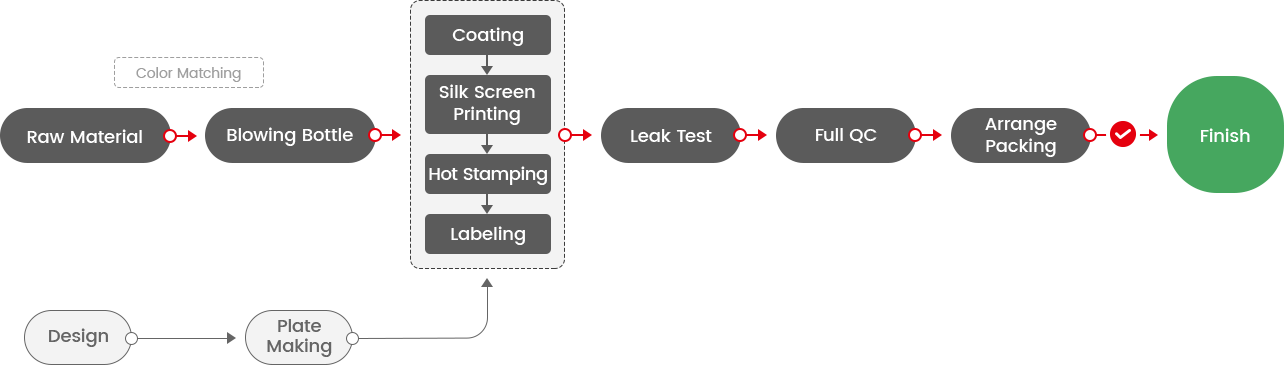

01. Silk Screen Printing

the printing plate will be wiped by UV printing ink, and then the printing plate transfer the ink on bottle , then move to UV light dryer to solidify the UV ink. Less 3 color better for screen printing

02. Hot Stamping

Silver, gold, Rose or any color transfers the foil by a stamping plate for attactive logo

03. Labeling

Stick white, transparent and metallic label for colorful printing design . Also shrink film label available for round edge and solid bottle

04. Coating

Metallic electroplating , spraying skin soft painting are widely used for solid PET bottle surface coating

HEYPACK©

Printing Test

Use Adheisve Sticker printing to test painting coming off or not

Leak Test

Airless machine space for filling liquid leaking test

Torque Test

Torque Tool for bottle closures use test

Heat Resistance Test

PET, PE and PP test heat resistant from 70℃ to 140℃

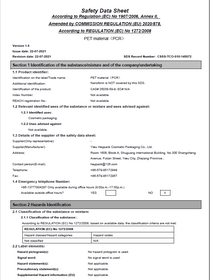

Test &

Certificate

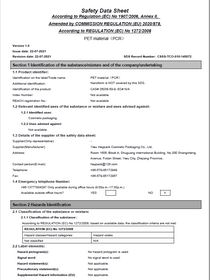

PCR

ROSH

Reach

MSDS

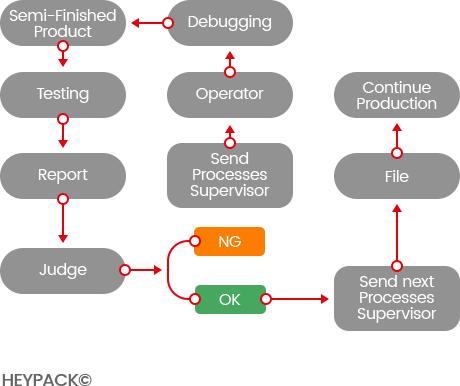

IN-PRODUCTION

Production

Process

video

01. Design Drawings

Engineer make container's structure and specification drawing according customer sketch to assure exactly size and apperance.

02. 3D Printing

3D digital printing build container shape 1:1 to present before molding

03. Mould Making

CNC, Spark and lathe processing workshop make 2-16 cavitys blowing bottle mold with stainless steel

04. Blowing Bottle

PE bottle made by extrustion+blowing process. Then cutting edge.

05. Surface Decoration

Engraving logo, Matte Frosting, Pearlizing, electroplating applied on bottle surface

06. Quality Control

Quality inspect mainly bottle deformatin, Burr edge, printing positioning and fallling, bottle thickness, size etc.

HEYPACK©

PRE-PRODUCTION

IN PRODUCTION

Process

& Lore

video

01. Silk Screen Printing

the printing plate will be wiped by UV printing ink, and then the printing plate transfer the ink on bottle , then move to UV light dryer to solidify the UV ink. Less 3 color better for screen printing

02. Labeling

Stick white, transparent and metallic label for colorful printing design . Also shrink film label available for round edge and solid bottle

03. Make Fluffy Feel

PE blowing bottle can make soft skin feeling surfface suit for body & skin packaging

04. Dye Plastic

Original colorful PE raw material for fast bottle produce

HEYPACK©

Printing Test

Use Adheisve Sticker printing to test painting coming off or not

Leak Test

Airless machine space for filling liquid leaking test

Torque Test

Torque Tool for bottle closures use test

Heat Resistance Test

PET, PE and PP test heat resistant from 70℃ to 140℃

Test &

Certificate

PCR

ROSH

Reach

MSDS

English

English